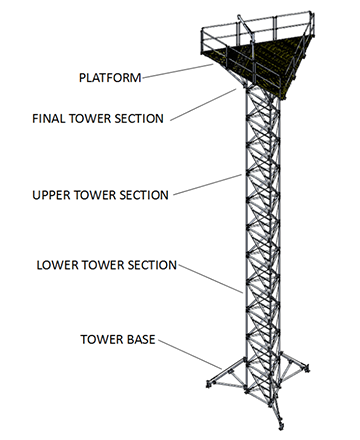

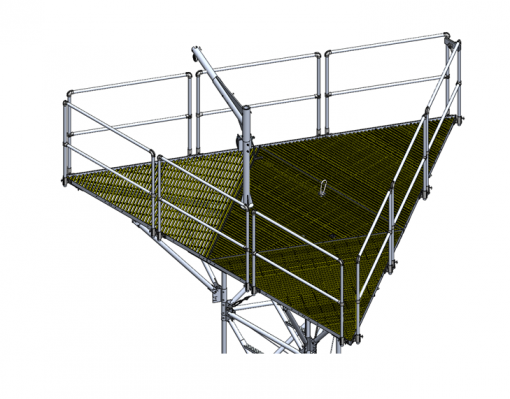

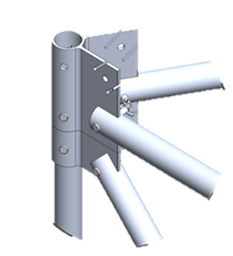

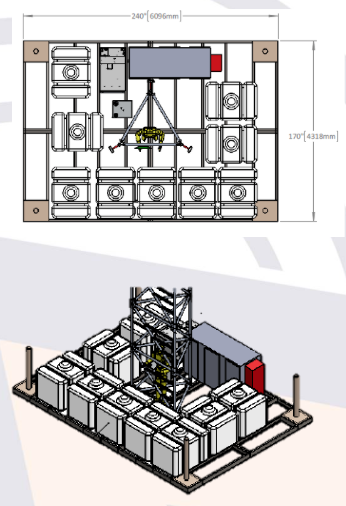

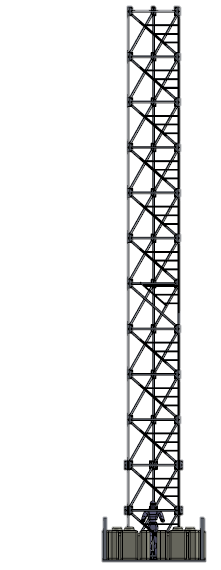

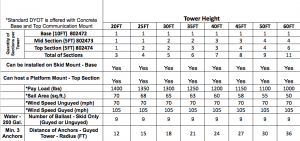

Aluma’s Design Your Own Tower option can provide a customized aluminum tower solution that can be climbed, relocated, and erected by as few as two people within eight hours. Our DYOT tower is ideal for locations where cranes and trucks can’t enter. Designing your own tower enables you to spend more time mission ready and less time, and money, setting it up.